Photochemical Reactor

Photochemical Reactor

- Inner immersion well

- Material of immersion well – Quartz

- Maximum Operating Temperature – 1200 degree celsius

- Application – To hold UV lamp and for water circulation

- Port – Inlet and outlet for water circulation, inner well used for UV lamp

- Outer Jacket

- Material of outer jacket – Glass / Borosilicate

- Maximum Operating Temperature – 600-degree celsius

- Application – Catalyst charging, Sampling of vent and thermowell for measurement of temperature

- Port – Three port (Customization of port is also available)

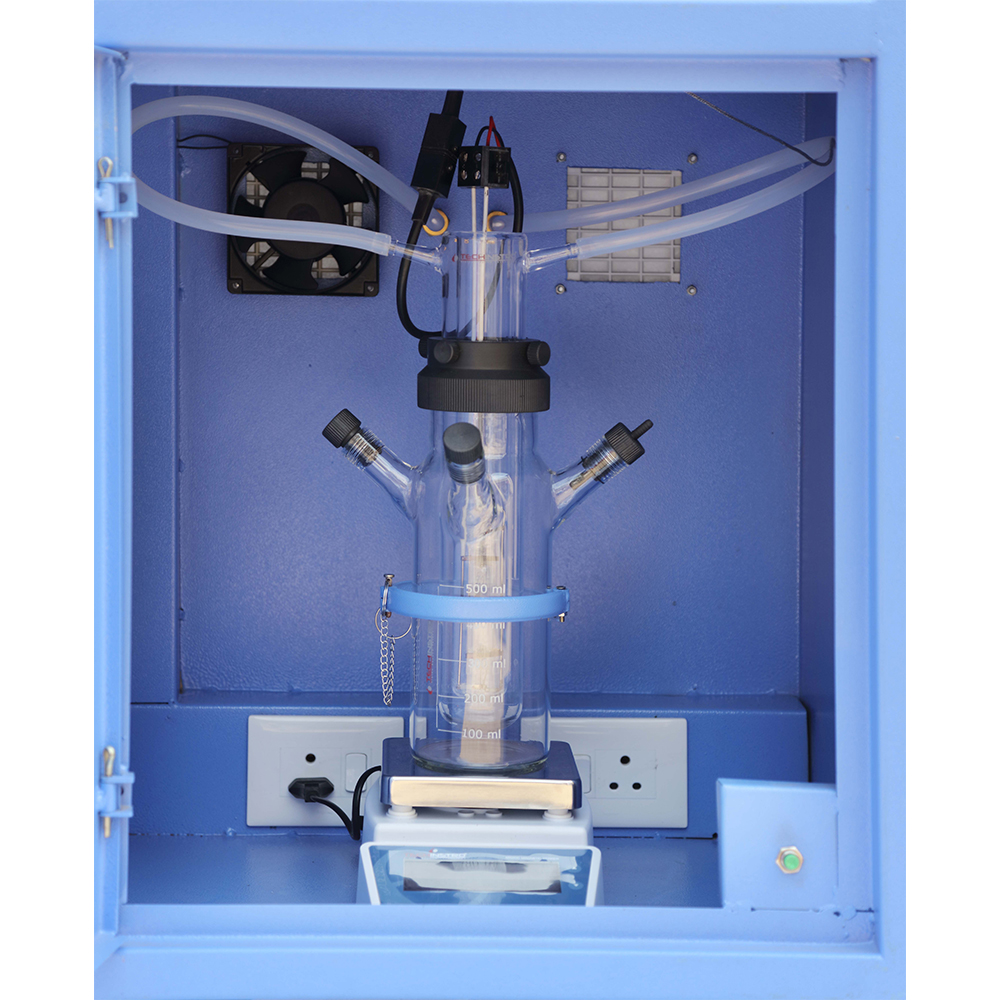

The photochemical reactor is used to carry out a photochemical reaction, water splitting, and photochlorination reaction. The reaction takes place in the presence of photon and catalyst. Hence it is called as photocatalysis reaction or photochemical reaction. The reactor is also known as the photocatalytic reactor. The photochemical reactors complete setup includes triple jacketed immersion well, medium and high-pressure mercury lamp, lamp power supply, a chiller for cold water circulation, safety cabinet and magnetic stirrer.

| 1. Capacity – 250ml | 2. Capacity – 500ml |

| 3. Capacity – 1000ml | 4. Capacity – 2000ml |

Full Description of Photochemical Reactor

The triple jacket immersion well consists of 2 part. One is inner double jacketed quartz well, and outer is borosilicate reaction vessel. The inner double walled immersion well is equipped with water inlet and outlet for water circulation. The lamp inserted into the double walled well and cold water flow required to maintained lamp temperature. The outer reaction vessel consists of three ports. One port used for catalyst and solvent feeding and other two ports used for gas inlet and outlet. The Borosilicate external reaction vessel with centre neck armoured TQR tapper quick fit design, where the inner quartz double jacked reactor has placed and sealed leak proof. Techinstro is the manufacturer and suppliers of the photoreactor having capacity ranges from 50 ml to 20 litres. In research, 500 ml reactor majorly used. The price of the assembly varied as per the capacity and setup requirement. The photochemical reactor assembly also includes UV protected goggles, silicon tubing for water circulation and Teflon fittings for gas inlet and outlet.

The photon plays a vital role in the photoreaction; therefore the mercury vapor lamp has been used to give specific wavelengths photon source. There are three types of light source accepted in the reactor, Low-pressure mercury lamp, Medium pressure mercury lamp, High-pressure mercury lamp. The low-pressure lamp consists of monochromatic wavelength and emits over 90% of their energy at 254 nm providing a useful source of ultraviolet radiation for the photocatalytic mechanism. The medium pressure mercury lamp emits UV light and covers the range from 250nm to 400nm with peaks at 254nm, 356nm, and 365nm is also known as UV lamp. Whereas the high-pressure mercury lamp emits visible light and covers the range from 360nm and above with peaks at 365nm, 420nm and 520nm is also known as a visible lamp. The selection of light source depends on wattage requirement and volume of the reactor. The UV output is approximately 18 -20 percent (%) of the light wattage. The UV lamp predominantly used as a photocatalytic reactor light source; hence it is known by UV reactor. We also supply xenon lamp source for the photochemical reactor on demand. The power supply or step down transformer is necessary since the light source requires quite high and constant voltage to start.

The photochemical reactor design can also customize as per clients requirements. Our research team invented an automated system provides fully UV protection to avoid direct exposure to UV light. The photochemical reactor has equipped with all the safety measures. The quartz photochemical reactor has been designed and developed for the batch as well as continuous processes as per requirement.

Applications of Photochemical Reactor

- Photochlorination

- Water Splitting

- Water treatment

- Pharmaceuticals industry

- Research and development laboratories

- Educational institutes

- Alternative Energy

- Environmental Engineering

Why Techinstro?

Techinstro has introduced and supplies photochemical reactor system as a unit which makes the installation simpler and increases operating efficiency. Photochemical reactor system comprises ultraviolet source; support equipment; power supply; and, electrical controls. Our reactor is designed and developed to be more productive and encompasses provision for irradiation by High, Low or Medium Pressure Mercury Lamps.

For specific and customized orders, you will have to communicate the required specifications via mail or call. We develop customized solutions to safeguard water from the damaging effects of microbial and chemical contamination. UV Reactors offer high yields and simplicity of control and the system is appropriate for “free radical” reaction mechanism. Its application is highly popular in fields such as halogenations of organic compounds, production of primary mercaptans, oxidation, isomerizations, polymerizations, hydrogen generation, solar application, Photolysis of toxic wastes etc.

Photochemistry is also used in the curing (polymerization) of specially formulated printing inks and coatings. Used in research and science, environment, green/clean energy, water splitting and so on. Our products are distinct, designed with an eye on easy operations and cleaning; optimum lamp spacing, uniform flow field, and significant efficiency advantages amongst others. The photo catalytic reactor is also used for derivatisation of Aflatoxins and enhanced detection.

The photocatalytic reactor comprises the inner double jacketed quartz immersion well and outer jacket of borosilicate. In UV photoreactor assembly, an immersion well fitted into the outer jacket in such way that the chances of leakage are negligible and which makes the system more productive. The inner diameter of immersion well designs and developed according to specially manufactured UV lamp, Xenon lamp, visible lamp, high pressure or medium pressure mercury lamp. In Triple Jacketed Photochemical Reactor the inner well used for UV lamp, Middle well used for water circulation and outer well used for the catalyst.

Our photocatalytic reactor work at optimum efficiency & consume minimum energy. As mentioned earlier, with help of advanced computer simulation tools, our UV reactors units have been optically and hydraulically optimized to facilitate efficient and cost-effective UV treatment. Our unique design gives them a compact footprint and ensures efficient use of space in a water treatment facility.