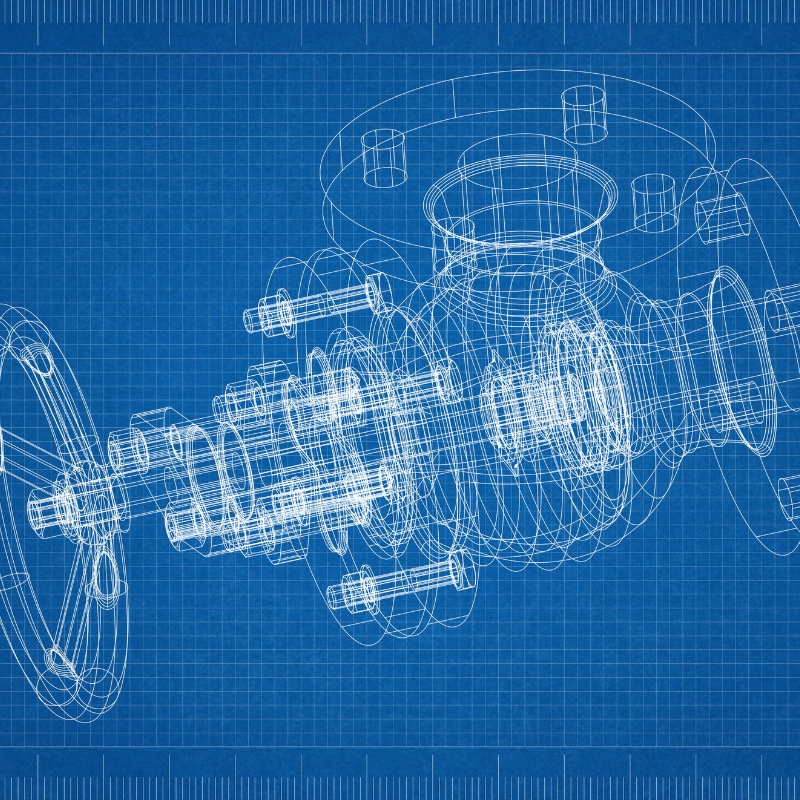

Pressure Safety Valve

Pressure Safety Valve

Features

- Set Pressure

- Orifice Size

- Inlet/Outlet Connections

- Body material

- Temperature Range

- Overpressure Limit

- Design Codes

- Lift Type

- Bonnet Design

- Certifications

- Seat Material

- Leakage Allowance

Specifications and Description of Pressure Safety Valve

A Pressure Safety Valve, often called PSV, is crucial in various industrial and mechanical systems. It ensures the safe operation of equipment by preventing over-pressurization. It plays an important role in safeguarding the machinery, personnel, and environment. Pressure Safety Valves operate on a simple yet effective principle. When the pressure within a system exceeds a predetermined threshold, the PSV automatically opens to release excess pressure. It prevents potential catastrophes like explosions or structural damage. It is akin to a pressure relief mechanism, allowing the system to vent extra pressure harmlessly.

Advantage

One of the main advantages of a Pressure Safety Valve is its ability to operate independently without external power sources or human intervention. It ensures reliability even in emergencies when power may be compromised. It’s a cornerstone of safety in industries such as oil and gas, chemical processing, and manufacturing, where high-pressure systems are prevalent.

Functions

Pressure Safety Valves (PSVs) come with specifications tailored to diverse industrial needs. These specifications include set pressure, orifice size, inlet/outlet connections, body material, temperature range, overpressure limit, design codes, lift type, bonnet design, certifications, seat material, leakage allowance, and optional features. Careful consideration of these specifications ensures the researchers choose the correct PSV for a specific application. Installing Pressure Safety Valves is mandated by safety regulations and standards, underscoring their significance in ensuring compliance and avoiding costly penalties. Routine maintenance and testing are also essential to guarantee their optimal functionality.

Properties Pressure Safety Valve

- Pressure Sensing: Designing of PSVs is such that it detects pressure levels within a system. It has mechanisms that respond swiftly when the pressure exceeds a predetermined set point.

- Automatic Operation: One of the most critical properties of PSVs is their ability to function autonomously. It does not require external power sources or human intervention to activate. This autonomous operation ensures rapid response in emergencies.

- Reliability: PSVs are famous for their high reliability and consistency in operation. We build them to resist harsh industrial environments and maintain performance over vast periods.

- Versatility: Users can mount PSV in various systems, including pipelines, boilers, pressure vessels, and more. They are adaptable to different pressure ranges and applications.

- Material Durability: We construct PSVs from durable materials, like stainless steel or other alloys, to endure the conditions of their respective environments.

- Resetting Capability: PSV has automatic resetting. After releasing the excessive pressure, it reaches a safe level. The resetting function allows the valve to resume its protective role without manual intervention.

- Leak Prevention: We engineer PSVs to prevent leakage during regular operation. It ensures that the pressurized system remains sealed when the valve is closed.

Applications of the Pressure Safety Valve

Pressure Safety Valves (PSVs) are indispensable components in many industries due to their pivotal role in ensuring the safe operation of pressurized systems. These valves find applications in diverse sectors, and their significance lies in preventing over-pressurization, which can lead to catastrophic accidents, equipment damage, or environmental hazards.

- Oil and Gas Industry: In this sector, users use PSVs in pipelines, refineries, and offshore drilling platforms. They protect against pressure spikes in processing equipment, storage tanks, and transportation vessels, safeguarding personnel and the environment from potential disasters.

- Chemical Manufacturing: Chemical plants often handle volatile substances under high pressure. PSVs are instrumental in maintaining the integrity of reactors, distillation columns, and storage tanks by venting excess pressure to prevent explosions or chemical releases.

- Power Generation: Whether fossil fuel-based or nuclear, power plants utilize PSVs in boilers and steam systems to control pressure fluctuations. These valves ensure the safe operation of turbines, generators, and other critical components.

- Pharmaceuticals: The pharmaceutical industry relies on PSVs to protect pressure vessels and autoclaves used in sterilization processes. They help maintain sterile conditions and prevent contamination.

- Food Processing: Pressure Safety Valves are essential in the food industry to maintain the integrity of pressure vessels used for cooking, sterilization, and processing. They ensure food safety and quality.

- Aerospace: Aircraft and spacecraft propulsion systems require precise pressure control. PSVs help to manage pressure changes during flight and critical operations.

- Manufacturing: Manufacturing processes often involve hydraulic and pneumatic systems that require pressure regulation. PSVs prevent system failures and ensure consistency in production.

- Utilities: Water treatment plants and distribution systems use PSVs to manage pressure in pipelines, tanks, and pumps.

- Hospitals: PSVs are essential in medical equipment such as autoclaves and sterilizers, which help to maintain the sterility of medical instruments and equipment.

- Maritime Industry: Pressure Safety Valves are vital on ships and vessels to control pressure in boilers, engines, and hydraulic systems, ensuring safe navigation and operation.

- Renewable Energy: PSV finds application in geothermal power plants, where steam and fluids need pressurizing. They maintain system safety and prevent equipment damage.

Safety Instructions

Prevention

Ensuring the safe and effective use of Pressure Safety Valves (PSVs) is essential to prevent over-pressurization and maintain operational safety in industrial processes. Ensure that the valve is securely and appropriately attached to the pressurized system.

Calibration

Calibrate PSVs to ensure they open at the correct set pressure. Conduct periodic testing to confirm that PSVs operate as expected. It can involve bench testing or in-situ testing to verify their functionality under actual conditions. Maintain comprehensive records of each PSV, including installation dates, maintenance and testing dates, and any issues or repairs performed. Proper documentation aids in tracking the history and performance of each valve. Ensure that PSVs meet industry-specific safety standards and regulations.

Installation

Install isolation and bypass valves upstream and downstream of PSVs. These valves enable safe isolation of the PSV for maintenance or replacement without shutting down the entire system. Maintain proper system design to prevent over-pressurization scenarios. It may involve incorporating relief devices at strategic points within the system and ensuring adequate ventilation and pressure relief pathways. Keep a stock of critical spare parts for PSVs to minimize downtime in case of repairs. It ensures that replacement parts are available when needed.

Implementation

Implement a routine inspection schedule to investigate signs of corrosion or damage to the PSV. Inspect the valve’s components, including the spring, disc, and seat, to ensure they are in good condition. Verify that the PSV’s set pressure matches requirements. Researchers should promptly correct deviations to ensure the valve opens at the intended force.

Why Choose Us?

Techinstro is renowned for its commitment to excellence, unparalleled service, and competitive pricing. With a legacy of over a decade in the chemical industry, we have earned a reputation as a trusted provider of high-quality products. Our expertise extends to Pressure Safety Valves (PSVs), where precision and safety are paramount. We take immense pride in delivering PSVs that exceed industry standards, making them ideal for various applications, including research and development projects. With its wealth of experience, our dedicated team is among the best in the market, ensuring that every PSV we produce is of the highest caliber. Our specialized QA staff ensures that every PSV leaving our facility meets global quality standards. We stand by our products’ reliability and performance, offering customization per our client’s needs. Our customer-centric approach means our professionals are available around the clock to provide guidance and support. Working with us guarantees top-tier products and a seamless and satisfying experience. We offer worldwide shipping, ensuring that your industrial operations benefit from the safety and reliability of our Pressure Safety Valves. To place orders or to learn more about our products, please don’t hesitate to contact us through our contact page.